Challenge

The challenge is to develop a 9xx nm diode laser system that robustly delivers 1 kW at 7.5mm*mrad. The diode laser system will provide optical and electrical interfacing for industrial application in the area of cutting and the system will demonstrate diode laser cutting of mild steel up to 6 mm, stainless steel up to 4 mm, and aluminium up to 3 mm.

Benefit

Plate cutting is the largest application field in a five billion Euro worldwide market for laser macro machining. Potential applications are laser cutting of different materials and thicknesses like:

- Mild steel up to 6 mm

- Stainless steel up to 4 mm

- Aluminium up to 3 mm

CUDE aims to establish an important milestone by validating the cost/performance relationship of novel direct diode lasers in an industrial environment. From the supplier side, there is benefit in standardisation and interfacing of technical equipment. This gives the supplier the opportunity to fit in different applications and to break into different markets. The user benefits from the low cost of ownership and simple implementation through standardisation and interfacing. Both DPI and Prima expect to benefit from the predicted growth in this segment of cutting.

Achievement

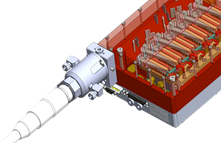

Currently, ultra-high brightness diode lasers provide kilowatts of output power with an efficiency of more than 40%. The planned combination of laser sources by wavelengthmultiplexing has been shown for 500 Watts power blocks, measuring a footprint of a notebook. Together with an increase in control speed, this leads to new integration concepts for industrial laser cutting equipment, spurring further optimization of the laser system for ‘plug-and-play’ operations with extended capabilities. Combining the diode design with fast control structures enables power modulation with tens of kilohertz. Metal processing can be improved towards higher cutting speeds, cutting quality, increased energy efficiency and lower maintenance requirements. Thus, lower costs and higher process quality can be expected. The new generation of 3D– laser cutting machinery will be equipped with direct laser diode, increasing the competitiveness of the laser system. Supplier Direct Photonics benefits from standardisation and interfacing of technical equipment, enabling him to fit in different applications and to emerge into different markets. End-user Prima Power benefits from low cost of ownership and simple implementation through standardisation and interfacing.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT