CHALLENGE

Disabled people depend on suitable and reliable vehicles which also need to fulfil all automotive and regulatory standards but the market is so small that car manufacturers cannot serve it with individualized solutions as each car is a one-off. For companies such as the French ACA, modification of series cars is the only way to provide mobility to such people. It involves dismantling of the car body and manual operation to cut the floor and to introduce new structures and devices. A laser based equipment that enables scanning and cutting would reduce the physically demanding cutting and the time consuming manual planning of the modification. For scanning and data processing, surface reflectivity and complex shape needs to be taken into account and for cutting, the three dimensional trajectory and different types of materials need to be taken into account. A significant advance in this production environment also requires a smooth integration of both solutions to bring the full benefit.

BENEFIT

Automated scanning of the car structure would remove the requirement for time consuming measurements as construction data files normally are not shared by the manufacturers. The automated transfer to an ICT solution that creates the path planning will help to derive suitable process parameters for the laser cutting process such that the cut can be executed with minimal burr and high success probability. With a direct transfer of this data to a cutting robot, an error free positioning of the cut would ensure minimal re-work on the car body. This would also reduce the need for re-painting and mechanical intervention and relieve workers from physically demanding cutting tasks. Overall, the closely integrated acquisition of geometry data, the planning of the cutting trajectory and the automated processing of the car body will reduce the overall time for this manufacturing step noticeably so that the cost for such car modification can be reduced significantly.

ACHIEVEMENT

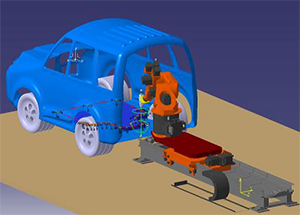

SCALP achieved its goals to demonstrate an automatic solution for 3D data acquisition from a high-speed scanner and its use for laser cutting with a 6-axis robotic arm on a real car. The overall processing time (3D modeling + cutting of the rear floor) of SCALP solution takes 2h with an accuracy of ±1mm instead of 8-10h for the manual current process without 3D CAD file.

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT