Nerea Otero from Aimen Technology Centre introduces the LASPRO assessment.

LASPRO - High speed infrared laser welding monitor and control

Challenge

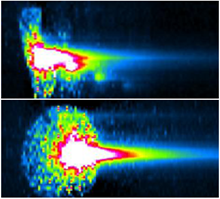

The assessment aims at monitoring the IR emission of the weld pool with a repetition rate of 10 kHz. Providing a tool for online detection of process instabilities in laser beam welding is one of the key challenges. Its benefits are received from the implementation of a closed loop control for the laser welding process.

Benefit

The focal plane arrays (FPA) developed in LASPRO will enable a new level in laser welding performance and reliability. Looking at the automotive industry, every car has roughly 4000 to 5000 welds which affect performance and safety. 20% of them are done by lasers. LASPRO will enable an increase of the share of laser welding by providing monitoring capability and online control.

- Enable aesthetical welding without the need of a finishing process, generating a good fit into other assemblies without weld seam interference

- Realise an increase in stiffness, enhancing the safety of cars

- Enable the reduction of flange heights, saving raw material

- Optimise speed and productivity

With the LASPRO focal plane array tool it will be possible to support the personnel in assuring quality which results in a decrease of cycle time and an enhancement in productivity. Additionally, the reduction of maintenance activities and a move from scheduled maintenance to maintenance on demand will lead to relevant reductions in production cost and an increase in uptime.

Achievement

A fast MWIR uncooled camera of NIT was successfully coupled to a standard laser processing head. Repeatability of the process is ensured by defining the defects that shall be detected in this type of laser welding; validation took place in form of posterior geometrical and metallurgical study. All in all, more than thirty welding seams were recorded and monitored. In some configuration, frame rates as high as 2000 Hz were used. The technology has excellent potential for helping to control laser parameters in real time and in line to an efficient performance/cost ratio. End-user CRF’s mission is the development and transferring of innovative systems and features, materials, processes and methodologies to improve the competitiveness of Fiat & Chrysler products. LASPRO enhances the existing technology: Supplier NIT benefits from the development of a specific software for its camera: LASPRO is enhancing its technology even more by developing specific software for NIT camera. This software is able to detect lack of fusion generated by three possible situations: 1) excessive gap between sheets, 2) grease between sheets and 3) small deformation in one sheet. It is able to detect a lack of fusion, something which can be generated.

LEA Partners

| Supplier | User | Research Partner |

|---|---|---|

|

|

|

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT