Rainer Kling introduces the TEETO assessment.

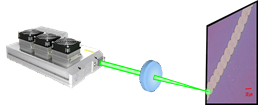

TEETO - Compact sub nanosecond laser source for thin film processing

Challenge

TEETO is developing laser-based equipment for processing of thin films with a sub-nanosecond laser source. One of its main goals is to provide a price competitive long-term stable laser source. As a result, productivity can be enhanced based on an increase of 30% in average power. The assessment also focuses on implementing a top hat energy distribution for thin film processing.

Benefit

TEETO aims to introduce new laser sources into the market of equipment manufacturers and users for the production of organic photovoltaics or organic LED’s (OLED). The challenge of achieving a top hat distribution of the energy is also a unique selling point. This entirely new technology will reach the new markets because of:

- The integration work provided by Alphanov during LASHARE will open the opportunity to test and implement alternative processing strategies.

- The process information gathered during this project will help the commercial prospection.

- Sub-ns microchip technology which will be able to spread best after the initial penetration enabled by this project.

Laser patterning with top-hat distribution would bring a lot of benefits, thanks to its flexibility and precision. Moreover, it is a one step process, which can easily be integrated in a roll-to-roll application. With the new equipment, MICEL will be able to provide ready to use indium tin oxide structures on film substrates to its customers at short lead times.

Achievement

Laser ablation of the TCO layer has shown the advantage over chemical processing technology: it is a one-phase process that offers flexibility and precision. Tests performed at Alphanov consisted of removing TCO of the PET substrate without degradation of the substrate. MICEL wants to implement laser patterning in its industrial process, to add value to its products, and to provide its customers with “readyto- use” ITO films. Another benefit of this project is the ability to supply a reliable replacement technology to ITO. TEEM PHOTONICS’ strategy is to provide laser sources at an interesting cost to equipment manufacturers and end-users that would be either OPV / OLED manufacturers. The integration of TEEM PHOTONICS technology could concern at least 50 manufacturing equipments per year in the next 5 years. The integration work provided by Alphanov during LASHARE offers the opportunity to test and implement alternative processing strategies. The process information gathered during this project will also help the commercial prospection. TEEM Photonics is going to offer more reliable lasers and thus robust processing equipment to these existing and potential partners.

LEA Partners

| Supplier | User | Pesearch Partner |

|---|---|---|

|

|

|

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT